Ferran Marias is MSC Tires' lead designer. He has been in the bike industry a long time and has earned himself the nickname of Mr Tires. Ferran has been working every aspect of tire design and manufacturing and even bicycle manufacturing.

He is the mad scientist behind many mythical models currently on the market some you'll likely be very familiar with. He knows just what it takes to make a World Cup Winning tire. He also piloted the Maxxis-MSC Downhill race team to 4 Championship titles and has even raced the UCI DH World Cup himself. His experience in racing and tyre design is legitimate - Just one year after the release of the line up of XC tyres we saw Vlad Dascalu take the U23 World Champs and series overall riding MSC Tires.

He talks to us about his experience in tire design and manufacturing, sponsorship and flat prevention and still getting pumped seeing new tires arrive at his desk.

Why start MSC Tires? What made you make that decision given MSC were a successful distrIbutor for Maxxis?

Since 1999 MSC has always been on the cutting edge of innovative products. When we focused our efforts on complete bikes we launched the lightest full suspension frame at the time - the MSC Koncept which was 1380g w/o shock. In 2005 we were already experimenting with gear boxes in bicycle frames.

Our partnership with Maxxis included distribution and marketing (MSC was responsible for the very popular Maxxis Cup race series. I also managed the Maxxis-MSC UCI DH team - which went on a winning streak of 4 UCI Titles

We also had deep collaboration with some of Maxxis most successful tires - Minion, Ardent, RaceTT, Wetscream to name a few. We also also worked in developing other tires for other brands.

We grew sales dramatically, but our distribution agreement was limited to Spain, France and Portugal which limited our potential growth. The partnership with Maxxis gave us tons of experience in the bicycle tire industry. With almost 20 years experience you learn all the ins and outs of the industry. With this knowledge we were confident to take on this challenging project and take it to the next level with MSC Tires.

What takes highest priority when you start a new tyre design in order to meet the performance of that particular segment? What do you think is most important about a tyre?

Firstly we look at the needs of riders. We don't just want to overload customers with new models or technology that will confuse them. We'll look at riders, our sponsored athletes, even our own employees to get all the feedback on where to start. We don't want to create an new tyre for the sake of it so we'll look at what gap it fills in the current lineup.

Our product philosophy is that our tire range must be simple and easy to understand even down to the technology and product names - it must be intuitive for the consumer.

When we started the Roller project, we initially started with a 2.20 width. When we printed it, we felt with the ETRTO 56-622, the tire was too wide for the tread patter and intended use. So we decided to reduce it to 2.10 (ETRTO 54-622) For our Tractor model we went with the 2.20 width and it was perfect. The Roller was the tire that Vlad Dascalu from Brujula Bike Team won his U23 UCI World Cup at Nove Mesto.

How do you start your tyre design - do you begin with selecting a casing and size / weight to suit the style of riding, then compounds then tread? Or do you draw the design on a napkin like we have heard of few stories from Aaron Gwin and Greg Minaar.

Most of the tread designs start with a paper sketch by hand, some are created in the office but the best ones are drawn on a dirty piece of paper having beers and hanging with friends. haha!

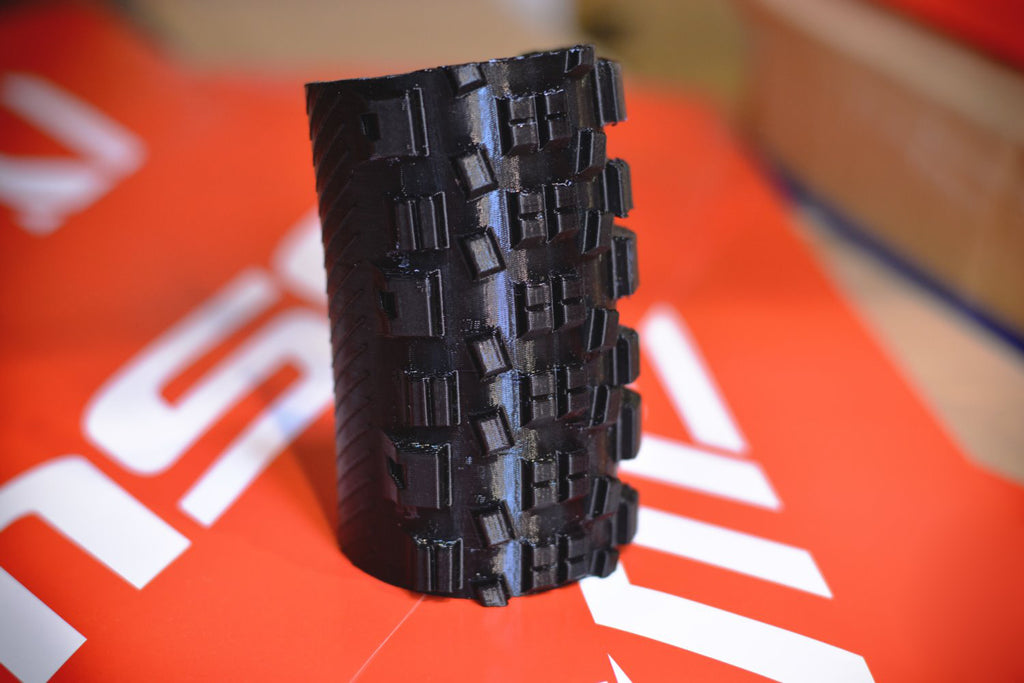

We'll turn the initial design into 3D files so we can fine tune the details. We'll then 3D print the samples, these will constantly be modified and we'll get to the final version. Sometimes it can take more then 20 samples printed before we get the "perfect" design

Once we have settled on the tread pattern we'll combine it with our previously developed casings. We'll then decide on the compound - but it doesn't end here. The balance between the compounds, tread and casing is critical. For example if you have knobs that are too soft with little material they will not be able to handle hours of abuse we put our tires through. This is where many years of experience is important - we already know how much material we can use with different compound "recipes" If you look closely at our Tractor tire you'll notice our unique micro texture on the center blocks and the internal ribbing on the smaller knobs, this is like playing magic with smaller volume and sticky tread knobs.

Do you benchmark your tyres against the competition? Being smaller, how does that give you a competitive edge?

Yes, naturally. Who doesn't? Being smaller is a positive for us. Compared to the big brands we can be more reactive and quicker at making changes. We don't have to pass through long protocols - If we need to make a small change along the line we can do it right away.

Being smaller we are also not forced to offer a mind numbing range of products, we can focus more energy and distill our technologies into our targeted tire line. We are also like family at our Barcelona headquarters - we are always sharing opinions and ideas. Employees, designers and riders we'll all get out on a ride together and talk about that perfect feeling tire.

What are your plans for your tire range? You have started with XC racing tyres - Roller and now have an enduro Gripper tyre. Any plans to expand the range into full DH racing and towards the fashionable 'Gravel' riding? - 650b and fat 700c?

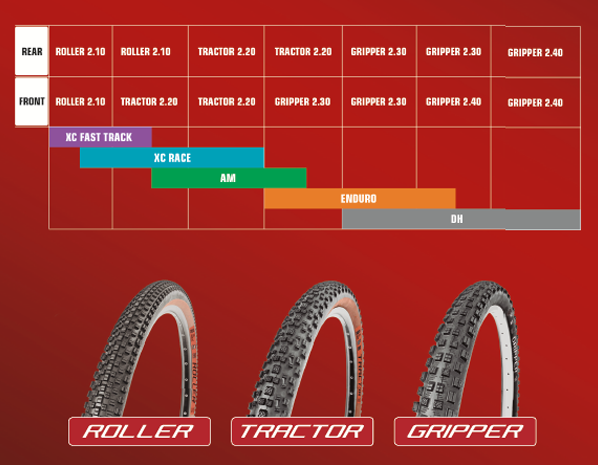

As mentioned earlier, we don't want to be offering a huge range of tires - so we introduce new models step by step after we are sure there is a need for it. In 2018 we started a 3-model MTB range that covered basically the whole range of riding. XC(Roller), Trail(Tractor), Enduro and DH(Gripper 2.30 and 2.40). We also have recently introduced the Tractor 2.80 Plus and Road Performance and Road Performance Plus.

We'll start introducing new models to fill the gaps between the current range. So we have the Roller 2.10 and Tractor 2.20 and we have the new Rock&Roller 2.10 which slots in perfectly between these two. And we have the Singletrack 2.20 which will fit in just below the Gripper 2.30.

We have just released the new Hot Seat - which is a dedicated downhill tire with a square profile with some of the most aggressive side knobs. Now combined with our XremShield casing, we can now focus on downhill races and DH athletes. Don't forget we have the Road range with the moto-inspired ultra grippy 2 compound Road Slick and then a Road Slick Tubeless which is almost complete. We don't stop!

What are you plans in the future for sponsorship? Do you have eyes on any EWS / World Cup Teams / ProTour Teams?

Initially we didn't want to go big for sponsorship until we have a complete and reliable range. Although saying that we partnered with the Brujula Race Team in 2018 & 2019, with some amazing results for the 2018 and 2019 season - U23 World Champ Stripes is not a bad effort

For next year we are ready to take the next step and we are discussing with some EWS and World Cup teams. ProTour team is very expensive right now for a smaller brand like us. But who knows?

We have seen an explosion of tire inserts in an attempt to prevent punctures - and we are seeing punctures at all levels of riding that no one can seem to resolve. What are you thoughts on this? We know Cesar Rojo is asking for a tire with really stiff sidewalls for stability and more puncture resistance - similar to motocross. What do you think about this?

Could we hope to see a collaboration with him - Two creative Barcelona based companies working together would be great.

In our opinion tire inserts are not the best solution. They add weight and make it difficult and time consuming to get a punctured or wasted tire changed. We are working on new casings and materials to prevent flats, we definitely think this is the best way to go. We are also working on something really revolutionary on this subject, but still under development.

Cesar is an old friend, we started racing together in the same family structure when we were kids. Future collaboration? Who Knows? He is one of the most talented and smartest guys in the bicycle industry.

As a new Ambassador i'm asked about your statement that your tyres are the 'Highest Quality' on the market. How do I present the advantages of MSC over say Maxxis, which are very popular in Australia given that Continental tyres get destroyed within a few rides and that Schwalbe has a terrible (but improving) reputation for quality

Our range is the most logical in the market. With our tire names you already know what type of tire you are getting, like the "Roller" or "Tractor" - this step makes it a lot easier for riders to enjoy our tires for the right intended use.

We have innovative designs for tire technology and some great solutions to current problems which really improve the performance overall - it's not just some special marketing terms. In such a short time our tires have already been race proven and we are constantly looking at evolving the casing and compound technologies to the best that is available. The confidence you get when you ride an MSC tire is different to others they offer predictability and they provide excellent bump absorption which improves the riders control. They are also very durable with our casings offering a very good balance of durability and feel. It's very difficult to get the right casing stiffness, absorption and grip but we feel we are close to it and it's definitely something that is obvious with our athletes and ambassadors with all their positive feedback.

The current Gripper has proven to be a fantastic, versatile tyre. Where did you start with the casing design for this tyre? The supershield seems really strong and stiff but isn't ridiculously heavy like a Maxxis DH casing? have you taken care to not use too much rubber in the casing sides? How did you achieve the strength of the casing?

The Gripper was designed to be a fast rolling tire for extreme conditions. It was not easy to develop a versatile tire with the right amount of grip and rolling speed that riders wanted.

We chose a more rounded structure to fit inner width rims from 30-35mm instead of the common squared off shape that other brands offer. With the Gripper's carefully designed side knobs we can get a very predictable tire yet still have lots of rolling speed in all types of terrain and it will work exceptional well in dry, mud and damp conditions.

The Hot Seat which has just been released has a new new tread design that offers a more squarer profile which offers unbeatable cornering predictability which is ideally suited to DH racing and riding it will also fulfill the needs of riders that just want to have the most aggressive tire out there.

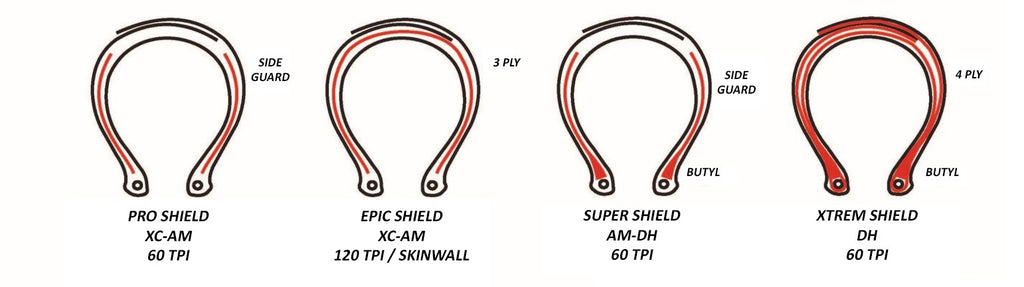

We've incorporated 2 casing options for the Gripper - ProShield (side guard) and SuperShield (side guard + butyl) and later on we'll have the XtremShield (4ply + butyl). With the new EpicShield(bead2bead) for marathon / XC we'll have 4 casing options that cover most of the riders needs. It's simple and limits confusion with all levels of riders.

We know earth friendly and sustainable manufacturing is important to bike riders. I mean no forest no mountain biking right? What steps are you taking to meet these goals?

We take the environment seriously. Having strong relationships with factories in Asia means we oversee the processes at every step. We are taking a huge effort in recycling productions materials and making manufacturing more efficient. Our next step is giving a second life to all our "waste" rubber making new products with the recycled materials.

At a grassroots level, we are working on a new bike park project in the Pyrenees based on responsible trail building which respects and works with the environment. It will invests in educating riders on reducing their footprint when riding. It's sounds crazy but we still find thousands of used tubes, gel packs and trash on the trails.

And on a closer level, our packaging on our MTB tires is actually a really high quality mud fender.

Thanks for your time Ferran! We look forward to seeing more of you tyre designs and athletes on the podium!